Design Tips

There are many common errors that you need to avoid during the design stage. Most mistakes are caused by nescient personnel without the necessary experience or the right tools at their disposal. Conversely, creative solutions and ingenuity abound in personnel with the right experience and the correct combination of hardware and software. Finding the right sulotion before happening is the most important part of the process.

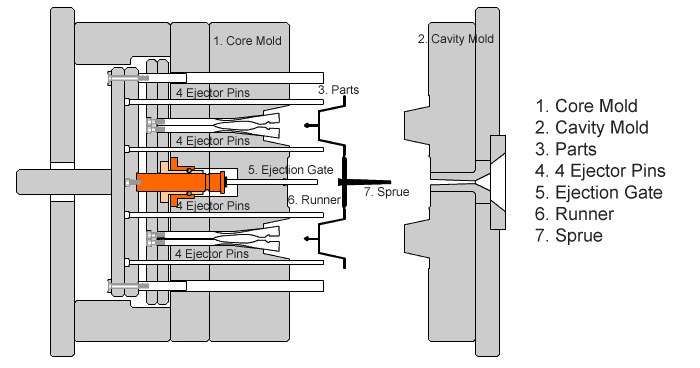

Injection Molding Diagram

The basic understanding of plastic molding process.

Selections of Resins

Choose right material for your product is a key to success.

| Abbreviation | Raw Material |

|---|---|

| ABS | Acrylonitrile Butadiene Styrene |

| ABS/PC | Acrylonitrile Butadiene Styrene / Polycarbonate |

| ETPU | Engineered Thermoplastic Polyurethane |

| HDPE | High Density Polyethylene |

| LCP | Liquid Crystal Polymer |

| LDPE | Low Density Polyethylene |

| LLDPE | Linear Low Density Polyethylene |

| PA6 | Nylon 6 |

| PA66 | Nylon 66 |

| PA12 | Nylon 12 |

| PBT | Polybutylene Terephthalate |

| PC | Polycarbonate |

| PEEK | Polyetheretherketone |

| PEI | Polyetheretherketone |

| PET | Polyethylene Terephthalate |

| PETG | Copolyester |

| PMMA | Acrylic |

| PLA | Polylactide |

| PP | Polypropylene |

| PPE/PS | Polyphenylene Ether / High Impact Polystyrene |

| PPS | Polyphenylene Sulfide |

| PS | Polystyrene |

| PSU | Polysulfone |

| PVC | Polyvinyl Chloride |

| SB | Styrene Butadiene |

| TPE | Thermoplastic Elastomer |

| TPU | Thermoplastic Polyurethane Elastomer |

| TPV | Thermoplastic Vulcanizate |

Mold Surface Finish

We take US Proto Lab’s surface process guideline for reference as below. It includes non-cosmetic, low-cosmetic and EDM finishes; bead-blast texturing; and high-end mold polishing. Standard finishes from least to most costly. Its maintenance cost increases as well.

| Level | Finish Description |

|---|---|

| PM-F0 | Non-cosmetic: finish to Protomold discretion |

| PM-F1 | Low-cosmetic: most toolmarks removed |

| PM-F2 | Non-cosmetic: Protomold discretion, EDM finish and/or toolmarks permissible |

| SPI-C1 | 600 grit stone, 10-12 Ra |

| PM-T1 | Protomold texture, SPI-C1 followed by light bead blast |

| PM-T2 | Protomold texture, SPI-C1 followed by medium bead blast |

| SPI-B1 | 600 grit paper, 2-3 Ra |

| SPI-A2 | Grade #2 Diamond Buff, 1-2 Ra |

Sink Mark -- Referance to Plastic Wall Thickness

Sink marks are small craters or depressions that develop in thicker areas of the injection molded prototype when shrinkage occurs in the inner portions of the finished product. The effect is somewhat similar to sinkholes in topography, but caused by shrinkage rather than erosion.

Sink marks are often caused when the cooling time or the cooling mechanism is insufficient for the plastic to fully cool and cure while in the mold. They can also be caused by inadequate pressure in the cavity, or by an excessive temperature at the gate. All else being equal, thick sections of the injection molded part take longer to cool than thin ones and so are more likely to be where sink marks are located.

In order to avoid the sink mark, mold temperatures should be lowered, holding pressure increased, and holding time prolonged to allow for more adequate cooling and curing. Reducing the thickness of the thickest wall sections will also ensure faster cooling and help reduce the likelihood of sink marks.

The following photos show the sink mark on thick solid plastic wall:

| Material | No More than |

|---|---|

| ABS | 0.149" |

| Acrylic | 0.59" |

| Nylon | 0.119" |

| Polycarbonate | 0.159" |

| Polyester | 0.129" |

| Polyethylene | 0.21" |

| Polyphenylene Sulfide | 0.19" |

| Polypropylene | 0.16" |

| Polystyrene | 0.16" |

| Polyurethane | 0.79" |

Tolerrence of Tool and Part, 2D/3D Measurements

Generally, with regards to tolerances, there are two types: tools and parts. For tools, machining tolerance can be maintained at a fixed ±.003 in, for example. For parts, tolerance will vary by size and type of material used during injection molding.

Selection of Plastic Colorent

Original resin usually comes with clear or white color. Custom colors are available on request by providing PMS chart. Our colorists have the knowledge and resources available to guarantee match accuracy with all kinds of materials such as PP, PE, Acylic, etc.

Batch Indicator -- for tracking the production

In many situations that the products need to be trucked for different reasons.

Injection Molding Process in different structures

Mold Basic

Bosses

Bubble

Cavity Half

Core Half

Cooling

Hardness of Material

Ejector Pin

Flash

Gate

Gibbs

Injection Cycle

Insert

Line of Draw

Runner

Shear

Short Shot

Sink Mark

Slide

Sprue

Cooling

This refers to round protrusions on plastic parts and molds.

Bubbles can be defined as a voided area trapped within a molded plastic part. It differs from a blister in that there is no surface protrusion with a bubble. Bubbles are usually caused by trapped gases or air pockets, but can also be caused by differential shrinking.

Concave in mold, which usually forms the outer surface of the molded part; depending on number of such depressions, molds are designated as a single cavity or multi-cavity.

it is the half of the mold where ejectors, side-action cams and other complex components are located. Also known as bottom half of the tool.

During injection molding, cooling is often the most time-consuming part of the process. Improper cooling – a common mistake – can increase cycle time and leave parts with cosmetic defects. Appropriate cooling channels can reduce cooling time and increase the productivity of a mold, which can reduce the price of the product.

Durometer measures of the hardness of a material. Hardness may be defined as a material's resistance to permanent indentation. The durometer scale was defined by Albert Ferdinand Shore, who developed a device to measure Shore hardness in the 1920s.

Pins that are pushed into a mold cavity from the rear as the mold opens to force the finished part out of the mold. Also called knockout pins.

Any excess material that is formed with and attached to the component along a seam or mold parting line.

A gate is a designed small opening to allow the melted plastics into the mold cavity, a successful gate design is determined by gate type, dimensions, location, it's deeply related with the materials been used, the type of mold plates, and economic factors. Gate design is one of the most important elements to influence injection mold quality and productivity.

Portion of the custom injection mold that holds the slide down so the cam can actuate it.

Refers to one set of moldings in a process to complete. Usually it only takes seconds according to the size of component.

Insert molding is the process of molding plastic around preformed metal inserts. This process is compatible with both thermoplastic and thermoset materials.

Line of draw is the direction in which the two custom injection mold halves will separate from the plastic part allowing it to be ejected without any obstructions from metal creating undercuts.

The channel that connects the sprue with the gate for transferring the melt to the cavities.

referred to when plastic enters into the mold and the melt is maintained by friction produced by speed and pressure. Too much shear can cause the plastic material to burn, too little can cause the material to freeze off causing short shot.

Shot Shot is the result of a plastic part not filling completely, including some or all of the details.

As the plastic solidifies in the mold, it freezes from the outside (near the mold surface) toward the inside. In thick sections, this results in inward pulling stresses (due to contraction) that can cause sink marks in the outer surfaces of the part. In addition, because thinner sections will freeze faster than thicker sections, there is also the possibility of stresses building up between thick and thin sections, resulting in part warpage.

Portion of custom plastic injection molds that is used for creating undercuts. Required for automatic injection molds.

The feed opening provided in injection molding between the nozzle and cavity or runner system.

During injection molding, cooling is often the most time-consuming part of the process. Improper cooling – a common mistake – can increase cycle time and leave parts with cosmetic defects. Appropriate cooling channels can reduce cooling time and increase the productivity of a mold, which can reduce the price of the product.

Contact Us: 972-354-4787